Microbiology of Milk and Dairy Products Notes Study Material

Microbiology of Milk and Dairy Products Notes Study Material: BSc is a three-year program in most of universities. Some of the universities also offer BSc Honours. Out of those, there are BSc Study Material, BSc Sample Model Practice Mock Question Answer Papers & BSc Previous Year Papers. At gurujistudy.com you can easily get all these study materials and notes for free. Here in this post, we are happy to provide you with BSc 2nd Year Microbiology of Milk and Dairy Products Notes Study Material.

Microbiology of Milk and Dairy Products Notes Study Material

Milk and dairy products constitute important items of our food. These products are very suitable for microbial growth. It thus becomes necessary to know the chemistry of milk, its spoilage, its method of preservation, and different dairy products where microbes play a positive rather than negative role.

Milk Composition. Milk is a complete food, with about pH 7.0 that is an aqueous solution of proteins, fats, and carbohydrates with many minerals and vitamins.

It may be seen that the major part is water. The specific protein, casein is infact a mixture of three long chains of amino acids suspended in fluid. It exists as calcium caseinate, a white product. Lactalbumin, another protein forms the surface skin of milk when heated to boiling. The major carbohydrate is lactose. The last major component of milk is butterfat, a mixture of lipids that can be churned into butter.

Milk spoilage. Spoilage occurs when microorganisms degrade the carbohydrates, proteins, and fats of milk and produce noxious end products.

It may be seen that Lactobacillus or Streptococcus species ferment the lactose to lactic acid and acetic acids turning the milk sour. They may produce enough acid to curdle the protein and form a sour curd. An attack of milk protein by Micrococcus, Bacillus, or Proteus results in sweet curdling. There is little acid formation. If milk becomes contaminated with Gram-negative rods of coliform groups of bacteria, such as E. coli or Enterobacter aerogenes, or Clostridium sp., there is acid and gas formation from the lactose.

This stormy fermentation causes the explosion of curds. Ropiness, like bread, develops from Alcaligenes, Klebsiella, and Enterobacter. Serratia marcescens causes the development of a red pigment.

Milkborne diseases. The important diseases are tuberculosis, brucellosis, and Q fever. The tuberculosis bacterium, Mycobacterium Bovis is consumed in milk and passes from the human intestine to the blood, from which it spreads to most organs. Brucellosis, a blood disease is caused by the Gram-negative rod, Brucella abortus. When transmitted to man through cow milk, the bacterium infects the blood-rich organs. Q fever, caused by rickettsia, Coxiella burnetti is also a milk-borne disease. Other important disorders associated with milk are primary atypical pneumonia, toxoplasmosis, anthrax, streptococcal infections, etc.

Pasteurization. The process was developed by Louis Pasteur in the 1860s to eliminate bacteria in wines. The process for milk was adopted in 1895. The primary object of this process is to eliminate disease-causing bacteria from milk, though the total number of bacteria is also very much reduced during this process. It reduces the chances of milk spoilage. There are two methods used for pasteurization:

(a) Holding method. This is an old process, in which milk is heated in a large tank at 62.9°C for 30 minutes. This method is also known as the LTLT method (low temperature, long time). To ensure uniform heating the milk is constantly stirred during the process.

(b) Flash method. This is a modern method and also known as HTST (high temperature, short time) method. Raw milk is first warmed using the heat of the previously pasteurized milk. It then passes through a hot cylinder at 71.6°C for a period of 15 to 17 seconds. The milk is then cooled rapidly in part by transferring its heat to the incoming milk.

A new method called ultra-pasteurization is also used in some dairy plants. Here the milk and milk products are subjected to heat at 82°C for three seconds only. Pasteurization destroys the pathogenic bacteria that may be transmitted by milk.

The pasteurized milk is graded into different grades on the basis of total bacterial counts. In different grades of milk, standards in respect of bacterial content per ml of milk vary from locality to locality.

Some bacteria are able to survive pasteurization, causing milk spoilage. Streptococcus lactis, Lactobacillus casei, and L. cremoris, produce acids, causing the protein to turn into curd. These bacteria which are able to endure the heat of pasteurization are called thermoduric. Pasteurization has no effect on thermophilic bacteria which grow well at 60°C to 70°C.

Laboratory Tests of Dairy Products

There are some tests that ensure the high standards of public health applied to the dairy industry. Some of the most commonly used tests are as follows:

1. Phosphatase test. An enzyme, phosphatase is normally found in milk. This enzyme in respect of heat tolerance is similar to the rickettsia, Coxiella burnetti (Q fever organism), or Mycobacterium Bovis (tuberculosis bacterium). It thus may be tested whether this enzyme is eliminated during pasteurization so that it could be assumed that these two microbes are also not present in the milk.

The milk sample is combined with disodium phenyl-phosphate. After a few minutes of incubation, a color reagent (CQC) is added. If phosphatase is present the contents will become blue in color. If there is no color change then it may be assumed that there is no phosphatase present. (Microbiology of Milk and Dairy Products Notes Study Material)

2. Standard plate count (SPC). This determines the total number of bacteria in a specified amount of milk, generally a milliliter (ml). This is used for grading milk. Under aseptic conditions, one ml of milk is added to 99 ml of distilled water or buffer. One ml and one-tenth ml samples are then transferred to sterile Petri dishes. These give 1: 100 and 1: 1000 dilutions of the milk respectively.

Other dilutions may also be prepared successively. A growth medium like plate count agar or tryptone glucose yeast extract agar is then added, and the milk samples are mixed with the medium. (Microbiology of Milk and Dairy Products Notes Study Material)

The dishes are incubated at 37°C for 24-48 hours. The plates are then placed on a counting device like a Quebec colony counter and the number of bacterial colonies is recorded. The colony count falling between 30 and 300 is selected and multiplied by the reciprocal of the dilution factor to obtain the bacterial count per ml of milk. (Microbiology of Milk and Dairy Products Notes)

3. Reduction test. This is a rapid test to find the relative amount of bacteria in a milk sample. The principle used is that the length of time for a colour change in a specific dye is proportional to the number of bacteria in the sample. A sample of milk is mixed with the dye solution (methylene blue or resazurin) and this is incubated. Due to the growth of bacteria and subsequent fermentation of lactose in milk, the electrons released are passed along to the dye molecules, reducing them. The enzyme involved is a reductase.

On reduction, methylene blue loses its colour, and resazurin changes from normal slate blue to pink or colorless form. Good quality milk normally shows minimal colour change even after five to six hours, whereas contaminated milk shows color change rapidly within two hours or so. (Microbiology of Milk and Dairy Products Notes Study Material)

4. Breed counting method. This method does not distinguish between live and dead cells. It is a direct count method in a known area of the microscopic field. The sample is spread (about 0.01 ml) over 1 cm2 of a microscope slide. The milk smear is dried and stained with Newman – Lampert stain. This stain fixes the smear, dissolves fat globules, and stains bacteria with methylene blue. The slide is then scanned under several oil immersion microscopic fields. Calculations are made as follows:

Area of one microscope field = 0.02 mm2

The area over which the milk sample is spread on the slide = 1 cm2 or 100 mm2

Then, no. of fields possible under the lens = 100 mm2 divided by 0.02 mm2

= 5000 fields

This number of fields is for 0.01 ml of milk. However, the final count is expressed as bacterial number per ml of sample. Thus, the factor is to be multiplied by 100.

i.e. 5000 X 100 = 500,000

This is the microscope factor i.e. 500.000

Suppose, 20 fields yielded an average of 0.4 bacteria per field. Then, the final count would be

0.4 X 500.000 (microscope factor)

= 200,000 bacteria per ml of milk sample

5. Antibiotic detection test. The test is performed to identify the presence of any antibiotics in the milk sample. It is likely that if the cow is treated with antibiotics against some diseases such as tuberculosis, Q fever, brucellosis, etc., the antibiotics may persist in the milk.

A paper disc is dipped into the milk and then applied to an agar plate inoculated with an organism like Bacillus subtilis. The presence of an antibiotic in milk will be indicated by the development of a zone of inhibition around the disc.

Important Fermented Foods

Microbiological production of food requires proper substrates for fermentation, microbial populations, and environmental conditions to obtain the desired end product. Quality control is essential in food production to ensure that the product is of high quality. The microbial processes used in food production traditionally employ microbial enzymatic activities to transform one food into another. In addition to this use of microbes to produce fermented food products, the microbial biomass is now considered a potential source of protein for meeting food needs.

Important fermented foods include (i) Fermented dairy products, (ii) Fermented meats, (iii) Leavening of bread, (iv) Alcoholic beverages, (v) Vinegar, (vi) Fermented vegetables, and (vii) Single cell protein. These, except alcoholic beverages and vinegar, will be considered here.

Fermented dairy (milk) products

Many products are made through microbial fermentation of milk, including buttermilk, yogurt, and many kinds of cheese. Fermentation is primarily carried out by lactic acid bacteria. The lactic acid pathway and the accumulation of lactic acid from the metabolism of milk sugar, and lactose are common in the production of fermented dairy products. The differences in the flavour and aroma of the various dairy products are due to additional fermentation products that may be present in very low concentrations.

1. Buttermilk, Sour cream, Kefir, and Koumis. Different products are produced by using different strains of lactic acid bacteria as starter cultures and different fractions of whole milk as the starting substrate.

Sour cream uses Streptococcus cremoris or S. lactis for producing lactic acid and Leuconostoc cremoris for characteristic flavour. The cream is starting substrate. Butter is normally made by churning cream that has been soured by lactic acid bacteria. Streptococcus cremoris or S. lactis is used to produce lactic acid rapidly and Leuconostoc citrovorum produces necessary flavors, Kefir and koumis, popular in Europe are fermentation products of S. lactis, S. cremoris, and other Lactobacillus spp, and yeasts.

2. Yogurt. It is made by fermenting milk with a mixture of Lactobacillus. bulgaricus and Streptococcus thermophilus at 40°C. Flavour is due to the accumulation of lactic acid and acetaldehyde.

3. Cheese. Cheese consists of milk curds that have been separated from the liquid portion of the milk (whey). The curdling of milk is done by enzyme rennin (casein coagulase or chymosin) and lactic acid bacterial starter cultures. Cheeses are classified as soft (high, 50-80% water content), semihard (about 45% water), and hard (low water content, less than 40%).

They are also classified as unripped if produced by single-step fermentation or ripened if additional growth is required during the maturation of the cheese to achieve the desired taste, texture, and aroma. Cottage and Cream, are soft, unripened cheeses; Brie, Camembert, and Limburger are soft, 1-5 months ripened cheeses; Blue, Brick, Gorgonzola, Monterey, Muenster, and Roquefort are semisoft, 1-12 months ripened cheeses, whereas Cheddar and Colby are hard, 3-12 months ripened cheeses.

Natural production of cheese involves lactic acid fermentation, with various mixtures of Streptococcus and Lactobacillus spp. used as starter cultures. The flavour results from the use of different microbial starter cultures, varying incubation times and conditions, and the inclusion or omission of secondary microbial species late in the process. Ripening involves additional enzymatic transformations after the formation of cheese curd. Swiss cheese formation involves late propionic acid fermentation with ripening done by Propionibacterium shermanii.

Various fungi are also used in the ripening of different cheeses. The unripened cheese is inoculated with fungal spores. Blue cheeses are produced by Penicillium spp. Roquefort cheese is produced by using P. roqueforti and Camembert and Brie by using P. camembert and P. candidum.

Fermented meats

Several types of sausage, such as Lebanon bologna, the salamis, and the dry and semidry summer sausages, are produced by heterotactic acid fermentation of meat during curing. Fermentation has a preservative effect and also adds flavour to the meat. Various lactic acid bacteria are used, but Pediococcus cerevisiae can be used for the controlled production of these products.

Leavening of bread

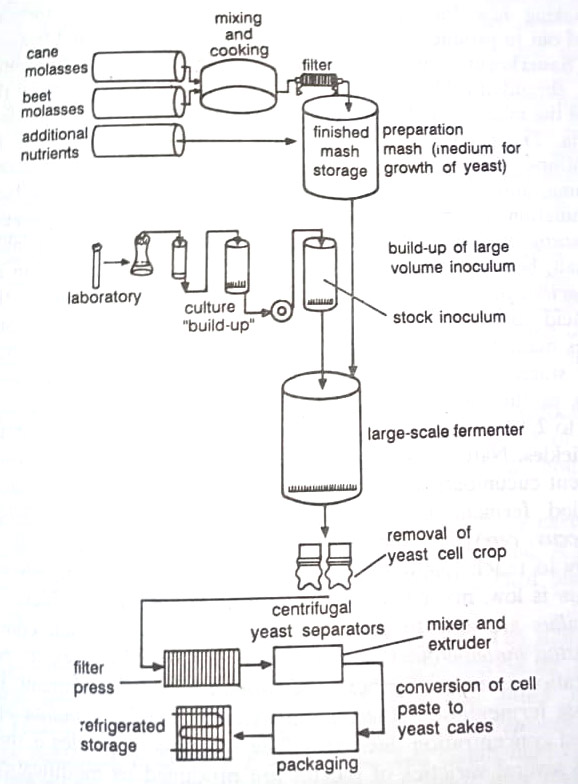

Yeasts are added to bread dough to ferment sugar, producing CO2 that leavens the dough and causes it to rise. The principal yeast used in bread baking is Saccharomyces cerevisiae, the baker’s yeast. The yeast is mass-produced in molasses-mineral salts medium at pH of 4.3-4.5 and 30°C, with a sugar concentration of 0.5-1.5%. Yeast cakes are normally formed and dried further.

Amylases in the dough convert starch to sugars and the yeast metabolizes these sugars to CO2 and ethanol. Besides yeasts, some bacteria such as Clostridium spp are also used for leavening the bread. After leavening, the bread is raised, as CO2 bubbles are trapped in the dough.

Fermented vegetables

Vegetables such as cabbage, carrots, cucumbers, green tomatoes, leafy vegetables, greens, olives, etc. are fermented by using lactic acid bacteria for making new food products. (Microbiology of Milk and Dairy Products Notes Study Material)

Other fermentations, such as soybeans, are carried out to produce especially desired flavours, aromas, and textures.

1. Sauerkraut. This is produced from a lactic acid fermentation of wilted, shredded cabbage. Salt, 2.25-2.5% is added to help extract the juice, control the microbiota during fermentation and maintain an even disposal of bacteria. The production of sauerkraut involves a succession of bacterial populations. Coliforms like Enterobacter cloacae, are prominent in the beginning and produce gas and volatile acids as well as some lactic acid. Accumulation of lactic acid causes a shift in the microbial community, and Leuconostoc mesenteroides, which grows well at 21°C and is not inhibited by 2.5% salt, becomes the dominant microbe.

Next in succession to appear is Lactobacillus Plantarum, which produces acid but not gas. During this phase, lactic acid concentration reaches 1.5-2%. Growth of L. Plantarum also removes mannitol, produced by Leuconostoc. Fermentation can be stopped at this stage. If the process continues, Lactobacillus Brevis, a gas-producer appears in the succession, which increases the lactic acid concentration further to 2.4% and also imparts a bitter acid flavour to the sauerkraut. (Microbiology of Milk and Dairy Products Notes Study Material)

2. Pickles. Natural microbiota (associated with cucumbers) can be used to ferment cucumbers under controlled temperature and salt concentration. Controlled fermentation can also be achieved by L. Plantarum and Pediococcus cerevisiae for 6-9 weeks. The salt concentration is increased gradually to reach finally to 15.9% NaCl. In the beginning, when the salt concentration is low, many bacterial genera such as Pseudomonas, Flavobacterium, and Bacillus are able to grow.

Later with an increase in salt concentration, Leuconostoc mesenteroides, and Streptococcus faecalis, appear. As the salt concentration increases further L. Plantarum becomes dominant. During the final yeast fermentation stage, Debaryomyces, Pichia, and Candida appear and lactic acid concentration decreases The sourness of pickles is due to lactic acid and several varieties of pickles are produced by modification of the basic process. (Microbiology of Milk and Dairy Products Notes Study Material)

3. Olives. Green olive production also involves lactic acid fermentation. Harvested olives are washed with a solution of NaOH to remove bitter phenolic glucoside. These are placed in a brine solution and lactic acid fermentation is allowed for 2-10 months. Within the first 2-3 weeks, Leuconostoc becomes dominant and lactic acid accumulates. The final stage is dominated by L. Plantarum, L. Brevis, yeasts, and various other bacteria also join at this stage. The final acidity is approximately 7.1% lactic acid.

4. Soy sauce. Several oriental fords are prepared by fermenting soybeans or rice. Soy sauce, a salty, brown, tangy sauce is produced from a mash consisting of soybeans, wheat, and wheat bran. The starter culture is produced by koji fermentation, a dry fermentation in which a mixture of soybeans and wheat is inoculated with spores of Aspergillus oryzae. The fungus grows on the surface accumulating various enzymes including amylases and proteinases. Various bacteria, normally dominated by lactic acid species also develop during this process.

After the starter has developed, it is dried and extracted. The extract is mixed with a mash containing sterile soybeans, autoclaved and crushed wheat, and steamed wheat bran. The mash with koji is incubated for some days at 30°C and then soaked with concentrated brine. The resulting mixture is called maromi. Mash is incubated for 10 weeks to 1 year. During this time microbes develop in succession.

The maturation begins with lactic acid bacteria and later involves alcohol fermentation by yeasts such as Saccharomyces rouxii and Torulopsis spp. The most important organisms during the process are A. oryzae and Lactobacillus spp.

5. Miso. This is also produced by using koji fermentation with A. oryzae. Steamed polished rice placed in shallow trays is used for producing starter culture. Koji is mixed with a mash of steamed soybeans, salt is added, and the process is allowed at 28°C for one week, at 35°C for 2 months, and at room temperature for several weeks. Miso is ground into a paste and combined with other foods.

6. Tempeh. This is an Indonesian food produced from soybean. The soybeans are soaked at 25°C, dried, and inoculated with spores of various species of Rhizopus. The mash is incubated at 32°C for 20 hours. The product is then salted and fried before eating.

7. Tofu and Sofu. Tofu (Japanese) and Sofu (Chinese) is a cheese-like products formed from fermented soybeans. Mucor spp. is used. A paste of soybean is curdled by adding Ca or Mg salts. Pressed, curd blocks are incubated at 14°C for one month.

8. Poi. This is fermented food from the Hawaiian Islands. The stems of the taro plant are steamed, ground, and subjected to fermentation for 1-6 days. During the first few hours, coliforms, Pseudomonas and other microbes dominate.

Then a succession occurs with Lactobacillus, Streptococcus, and Leuconostoc becoming dominant. Finally, yeasts and Geotrichum candidum flourish. Fermentation products, chiefly lactic acid, acetic acid, formic acid, ethanol, and CO2 contribute to the characteristic texture, flavour, and aroma of poi. (Microbiology of Milk and Dairy Products Notes Study Material)

Single Cell Protein (SCP)

The term SCP is used today to include “a microbial biomass, from uni- as well as multicellular microorganisms which can be used food as such or as a feed additive”. Microbes used for SCP production include algae, bacteria, yeasts, and filamentous fungi. Mushroom cultivation, where basidiocarps of the fungus are eaten as such is also included in SCP.

Because of their rapid growth, high protein content, and ability to utilise a range of organic substrates of low cost and even some industrial and agricultural wastes, microbes are potentially valuable sources of animal food. The growth of the science of animal nutrition has led to the development of a new industry based on the cultivation of microorganisms for use as a supplement in animal feeds (SCP industry).

The proteins of selected microbes contain all the essential amino acids. On average, the microbial biomass contains about 45 to 55% protein and other essential nutrients as such. Thus SCP production has several advantages over traditional methods of protein production for food and feed. (Microbiology of Milk and Dairy Products Notes Study Material)

In addition to the above-mentioned characteristics of microbes (rapid growth, high protein content, and potential of utilising a range of low-cost substrates), this method is independent of seasonal and climatic conditions Rapid conversion rate by microbes should be clear from that a bullock weighing 500 kg produces about 0.4 kg of protein in 24 hours, whereas under favourable conditions, 500 kg of yeast produces over 50,000 kg of protein in the same period. (Microbiology of Milk and Dairy Products Notes Study Material)

Research on the concept of SCP production began during the 1960s by some oil companies when petroleum was inexpensive and appeared to be economically an attractive substrate for SCP growth. (Microbiology of Milk and Dairy Products Notes)

Both autotrophs and heterotrophs are used in SCP. For instance, algae like Chlorella, Scenedesmus, Spirulina, etc. have been grown in various warm ponds as a food source. The use of solar energy by these autotrophs reduces the number of fuel resources required for SCP. In India, research work is in progress at CFTRI (Central Food Technology Research Insitute), Mysore on Spirulina as a supplement to food. The alga is cultured, dried, powdered, and used as tablets. It contains 60% proteins, vitamins, and unsaturated fatty acids.

Among heterotrophs, mushrooms are being cultivated the world over on different solid substrates including agricultural wastes (such as straw and compost) employing SSF (solid-state fermentation technology for consumption as such. Besides the solid agricultural wastes, other renewable carbon sources are also used, such as molasses, whey, and effluents of distilleries and confectionaries, potato and canning, brewing, and wood pulp industries. The non-renewable sources include fossil carbon sources such as petrol, gaseous hydrocarbons, methanol, ethanol, etc. (Microbiology of Milk and Dairy Products Notes Study Material)

Production of yeast from petroleum

Initially, cheap sources of carbohydrates (whey, molasses, pulp wastes) were used for growing food yeasts. Since it proceeds under aerobic conditions, all compounds that can support respiratory metabolism may serve. This led to the development of the idea of the use of petroleum as a substrate. In highly reduced organics, growth yield is very high. In areas where petroleum is cheap, it can be used for SCP growth. The British Petroleum Corporation built an industrial unit in France for the cultivation of Candida lipolytica in an aqueous emulsion of crude petroleum. (Microbiology of Milk and Dairy Products Notes Study Material)

This yeast can oxidize aliphatic, unbranched hydrocarbons of chain length C12 to C18, compounds that comprise part of the complex mixture of alkanes present in crude petroleum. After this yeast has been grown, the dewaxed petroleum is much more easily refined.

Thus refining process is simplified and protein is produced. Other such plants for producing yeast from petroleum were built in Italy and Japan. But the projects may be abandoned due to the reason byproducts contain benzopyrene, a carcinogen, and other residual hydrocarbons. (Microbiology of Milk and Dairy Products Notes Study Material)

Yeasts are excellent candidates for commercial SCP. Yeast-based SCP has a high vitamin content. Various yeasts, including species of Saccharomyces, Candida, and Torulopsis can be grown on waste materials, recycling these into useful sources of food. In ex-USSR, there is a huge commercial production of Candida yeast protein from hydrolyzed peat producing about 1.1 million tons of yeast protein each year.

Production of bacteria from petroleum

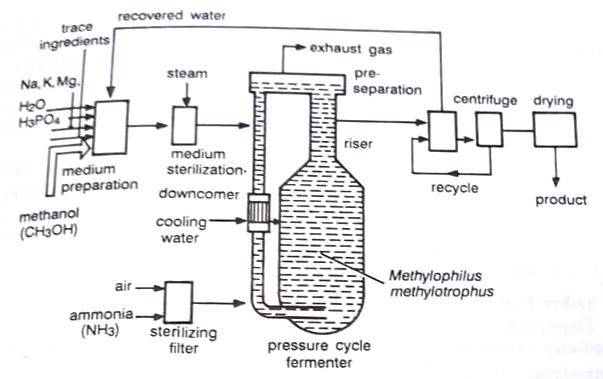

In 1976 Imperial Chemical Industries (ICI) began construction of a plant in Billingham, England, to make SCP by growing the methylotroph, Methylophilus methylotrophs (a bacterium that grows on C1 compounds), on methanol in a single huge fermentor.

The bacterium is grown on methanol, derived from methane, and the cell crop is harvested, centrifuged, dried, and sold in pellet or granular form. (Microbiology of Milk and Dairy Products Notes Study Material)

The SCP product is marketed as Preteen. Air is introduced in the base, methanol is injected through 300 ports inside the fermentor. Fermentor is operated as a continuous growth chamber. However, due to the dramatic increase in oil price, this can no longer survive as a cheap method of protein production as compared to soybean, pulses, and fish meal. Methanol derived from cellulose or other cheap sources in the future may revive the process. (Microbiology of Milk and Dairy Products Notes Study Material)

SCP is primarily produced as animal feed. Due to the high (6-11)% concentration of nucleic acids, there are problems in human consumption. It may lead to several disorders. Chicken and other animals can be grown on SCP rather than on plant materials. Work is in progress for the production of SCP, suitable and safe for human consumption. (Microbiology of Milk and Dairy Products Notes Study Material)

BSc Microbiology of Milk and Dairy Products Notes Study Material

BSc 2nd Year Sample Model Practice Mock Test Question Answer Papers